Recent research from the Massachusetts Institute of Technology (MIT) has revealed surprising hidden atomic patterns within metal alloys, challenging the long-held belief that atoms mix randomly during the manufacturing process. This groundbreaking study indicates that these patterns persist even after intense processing, potentially leading to improved control over the properties of metals.

New Findings on Atomic Arrangements

Scientists have discovered subtle atomic configurations in metal alloys that can be adjusted to enhance key properties such as mechanical strength, durability, and radiation tolerance. The research team employed advanced computer simulations to investigate an alloy composed of chromium, cobalt, and nickel (CrCoNi) during common manufacturing processes, including rapid cooling and extensive stretching.

According to Rodrigo Freitas, a materials scientist at MIT, “This is the first paper showing these non-equilibrium states that are retained in the metal.” He emphasized that current manufacturing practices do not account for the chemical order that the study highlights, which has significant implications for future metal production.

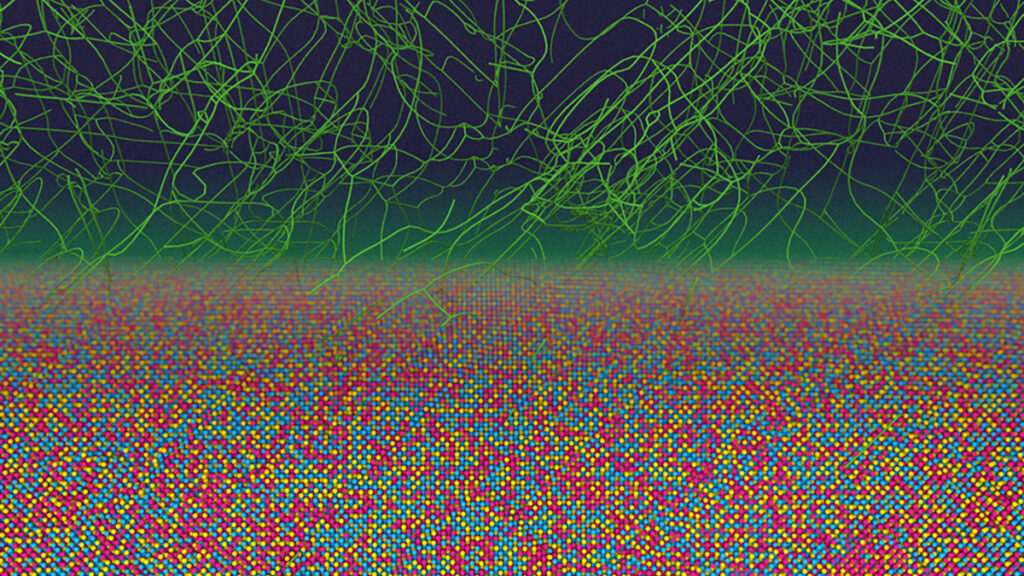

The detailed simulations tracked millions of atoms, uncovering familiar atomic patterns that surprisingly remained intact despite the rapid deformations. Additionally, researchers identified new patterns, referred to as “far-from-equilibrium states,” which arise during manufacturing processes.

Understanding the Role of Defects

A key finding of this research is the role of defects, or dislocations, in the crystal structures of metals. These defects, which form when metals are heated, cooled, or stretched, resemble atomic-level scribbles that assist metals in managing the strain they encounter. Contrary to prior assumptions that such deformations would obliterate short-range order (SRO), the simulations indicated a predictable shuffling of atoms.

Freitas explained, “These defects have chemical preferences that guide how they move. They look for low energy pathways, so given a choice between breaking chemical bonds, they tend to break the weakest bonds, and it’s not completely random.” This insight into atomic behavior opens avenues for the fine-tuning of metal properties, which could impact various applications, including nuclear reactors and spacecraft.

The study concludes that it is impossible to completely randomize the arrangement of atoms in metals, regardless of the processing techniques employed. Freitas remarked, “The fact that you cannot completely mix something together, people didn’t see that coming.” This revelation challenges conventional wisdom and suggests new directions for research into metal alloys.

Published in Nature Communications, this research lays the groundwork for future studies aimed at leveraging these hidden atomic patterns to enhance material properties and expand the possibilities for advanced manufacturing techniques.