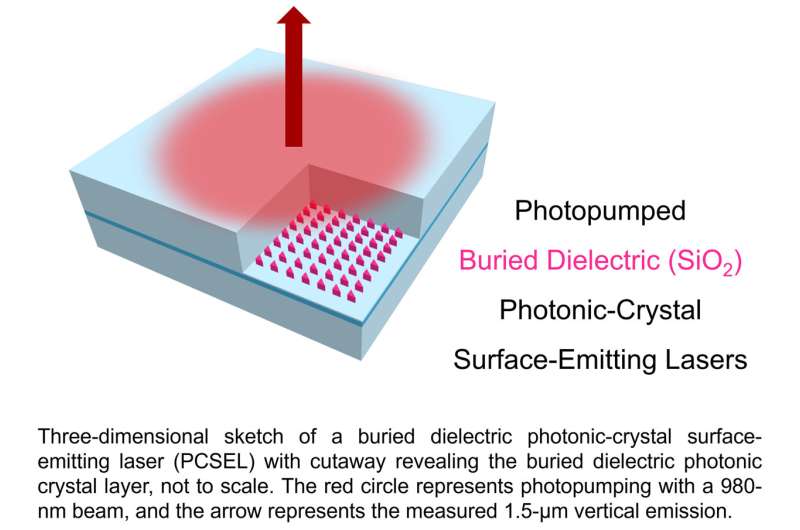

A team of researchers from The Grainger College of Engineering at the University of Illinois Urbana-Champaign has achieved a significant breakthrough in laser technology. They demonstrated photopumped lasing from a buried dielectric photonic-crystal surface-emitting laser, operating effectively at room temperature and emitting light at an eye-safe wavelength. This advancement, published in the IEEE Photonics Journal, marks an important step forward in laser design and has potential applications in defense technologies.

The lab, led by Professor Kent Choquette, has been investigating vertical-cavity surface-emitting lasers (VCSELs) for years. These lasers are widely used in everyday devices such as smartphones and laser printers. However, in early 2020, the Choquette lab shifted its focus to a novel type of laser called photonic-crystal surface-emitting lasers (PCSELs), inspired by research from a Japanese group. PCSELs utilize a photonic crystal layer to produce laser beams with enhanced characteristics, including high brightness and narrowly focused spot sizes. Such features make PCSELs particularly useful for defense applications, such as LiDAR technology used in battlefield mapping and navigation.

With funding from the Air Force Research Laboratory, Choquette’s team aimed to explore the capabilities of PCSELs and contribute to the maturation of this emerging technology. Graduate student Erin Raftery, the lead author of the study, emphasized the importance of their work, stating, “We believe PCSELs will be extremely important in the future. They just haven’t reached industrial maturity yet, and we wanted to contribute to that.”

Traditionally, PCSELs are constructed using air holes, which are embedded within the device as semiconductor material regrows around their perimeter. However, this process can lead to issues, as semiconductor atoms often rearrange and fill these holes, disrupting the photonic crystal structure. To address this challenge, the team replaced the air holes with a solid dielectric material, specifically silicon dioxide. This change helped maintain the integrity of the photonic crystal during the regrowth phase.

Raftery recounted the initial uncertainty surrounding this approach: “The first time we tried to regrow the dielectric, we didn’t know if it was even possible. Ideally, for semiconductor growth, you want to maintain that very pure crystal structure all the way up from the base layer, which is difficult to achieve with an amorphous material like silicon dioxide. But we were actually able to grow laterally around the dielectric material and coalesce on top.”

Looking ahead, experts in the field anticipate that these innovative lasers will find applications in various sectors over the next two decades. Potential uses include autonomous vehicles, laser cutting, welding, and free-space communication technologies. Meanwhile, the Illinois team plans to refine their current design by incorporating electrical contacts, allowing the laser to connect to a current source for power.

Choquette highlighted the collaborative nature of the project, stating, “The combined expertise of Erin and members of the Minjoo Larry Lee group, as well as the facilities and expertise at the Air Force Research Laboratory on Wright-Patterson Air Force Base, were necessary to accomplish this result. We look forward to diode PCSEL operation.”

The findings of this research represent a pivotal advancement in the field of laser technology, with the potential to reshape various industries through innovative applications. As the team continues to develop this technology, the implications for defense and beyond remain promising.