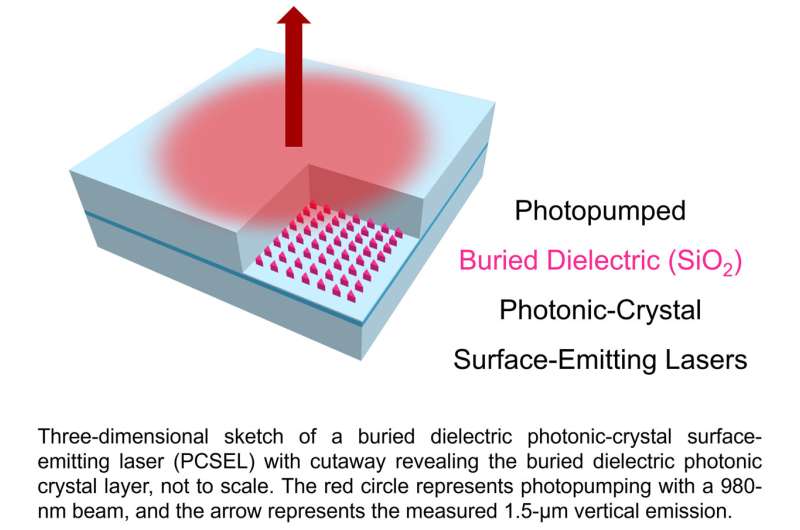

Researchers at The Grainger College of Engineering at the University of Illinois Urbana-Champaign have made a significant breakthrough in laser technology. They have successfully demonstrated photopumped lasing from a buried dielectric photonic-crystal surface-emitting laser, which operates at room temperature and emits light at an eye-safe wavelength. This advancement, published in the IEEE Photonics Journal, has the potential to enhance current laser designs and expand their application in various fields, particularly in defense.

The lab, led by Professor Kent Choquette, has been at the forefront of research on vertical-cavity surface-emitting lasers (VCSELs) for decades. These lasers are widely used in everyday technologies such as smartphones, laser printers, and barcode scanners. In early 2020, the Choquette lab shifted its focus to a new class of lasers known as photonic-crystal surface-emitting lasers, or PCSELs. These lasers utilize a photonic crystal layer to achieve high brightness and narrow spot sizes, making them ideal for applications like LiDAR, which is crucial for battlefield mapping and target tracking.

With funding from the Air Force Research Laboratory, the team aimed to explore the capabilities of PCSELs and contribute to their industrial development. Graduate student Erin Raftery, the lead author of the study, expressed optimism about the future of this technology, stating, “We believe PCSELs will be extremely important in the future. They just haven’t reached industrial maturity yet, and we wanted to contribute to that.”

The fabrication of PCSELs typically involves using air holes, which can lead to structural issues during the semiconductor regrowth process. To address this challenge, the Illinois engineers replaced the air holes with a solid dielectric material. By embedding silicon dioxide within the semiconductor regrowth, they successfully created a proof-of-concept design featuring buried dielectric features.

Raftery noted the significance of this achievement, saying, “The first time we tried to regrow the dielectric, we didn’t know if it was even possible. Ideally, for semiconductor growth, you want to maintain that very pure crystal structure all the way up from the base layer, which is difficult to achieve with an amorphous material like silicon dioxide. But we were actually able to grow laterally around the dielectric material and coalesce on top.”

The implications of this research are substantial. Experts predict that these advanced lasers could be utilized in autonomous vehicles, laser cutting, welding, and free-space communication within the next two decades. In the near term, the Illinois team plans to refine their design further, incorporating electrical contacts that would allow the laser to be powered by a current source.

Choquette emphasized the collaborative effort behind this innovation, stating, “The combined expertise of Erin and members of the Minjoo Larry Lee group, as well as the facilities and expertise at the Air Force Research Laboratory on Wright-Patterson Air Force Base, were necessary to accomplish this result. We look forward to diode PCSEL operation.”

As researchers continue to enhance this technology, the future of lasers appears promising, offering new solutions for both commercial and military applications.

For further information, refer to the study by Raftery et al. titled “Photopumped Buried Dielectric Photonic-Crystal Surface-Emitting Lasers” in IEEE Photonics Journal (2025). DOI: 10.1109/JPHOT.2025.3561087.