Recent research led by the Massachusetts Institute of Technology (MIT) has uncovered surprising atomic patterns within metal alloys, challenging long-held beliefs about their manufacturing processes. Traditionally, it was believed that the atoms in metal alloys were mixed randomly during production. However, this study reveals that specific atomic arrangements persist even after significant deformation.

Revolutionizing Metal Manufacturing

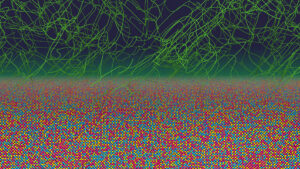

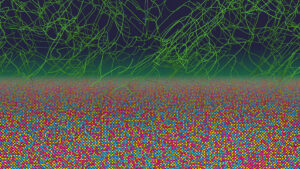

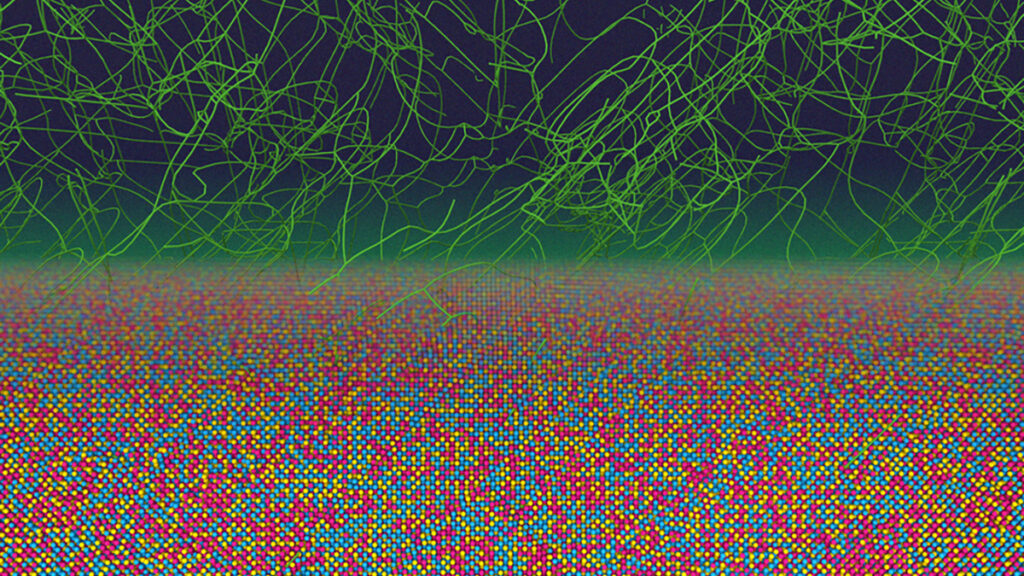

This groundbreaking study, detailed in Nature Communications, demonstrates how subtle patterns in metal alloys can be manipulated to improve various properties, including mechanical strength, durability, and radiation tolerance. The researchers employed advanced computer simulations to observe the behavior of millions of atoms within a chromium, cobalt, and nickel (CrCoNi) alloy during processes such as rapid cooling and extensive stretching, which are common in manufacturing.

According to Rodrigo Freitas, a materials scientist at MIT, this research is the first to document the retention of non-equilibrium states in metals post-manufacturing. He stated, “This chemical order is not something we’re controlling for or paying attention to when we manufacture metals.” The findings suggest that these hidden patterns can be crucial for tailoring the properties of metals for specific applications.

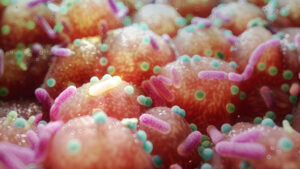

Unveiling Atomic Patterns

The researchers identified both familiar patterns and new ones that they term “far-from-equilibrium states.” These patterns are crucial for understanding how atoms behave under stress. Traditionally, it was assumed that the deformations and movement of defects in metals would eliminate any sort of short-range order (SRO). However, the study shows that atomic rearrangements follow predictable paths, influenced by the defects that occur during heating and cooling.

“These defects have chemical preferences that guide how they move,” Freitas explained. “They look for low energy pathways, so given a choice between breaking chemical bonds, they tend to break the weakest bonds, and it’s not completely random.” This insight highlights a significant shift in understanding how metals can be engineered at the atomic level.

The implications of these discoveries extend to various industries, including nuclear reactors and spacecraft. By understanding how manufacturing processes influence atomic arrangements, future research can focus on how to optimize metal properties for specific uses. Freitas concludes, “You can never completely randomize the atoms in a metal. It doesn’t matter how you process it. The fact that you cannot completely mix something together, people didn’t see that coming.”

As researchers continue to explore these hidden atomic patterns, the potential for innovative applications in material science appears vast. This study not only enhances our understanding of metal alloys but also sets the stage for new manufacturing techniques that could revolutionize the industry.