Eliminating Per- and Polyfluoroalkyl Substances (PFAS) is emerging as one of the most significant environmental challenges globally, with an estimated 15,000 human-made chemicals contributing to severe contamination of soils and waterways. These substances do not break down naturally and can accumulate in the environment, posing serious health risks to humans, animals, and plants. With growing awareness of their dangers, scientists and governments are prioritizing the development of effective methods for PFAS removal.

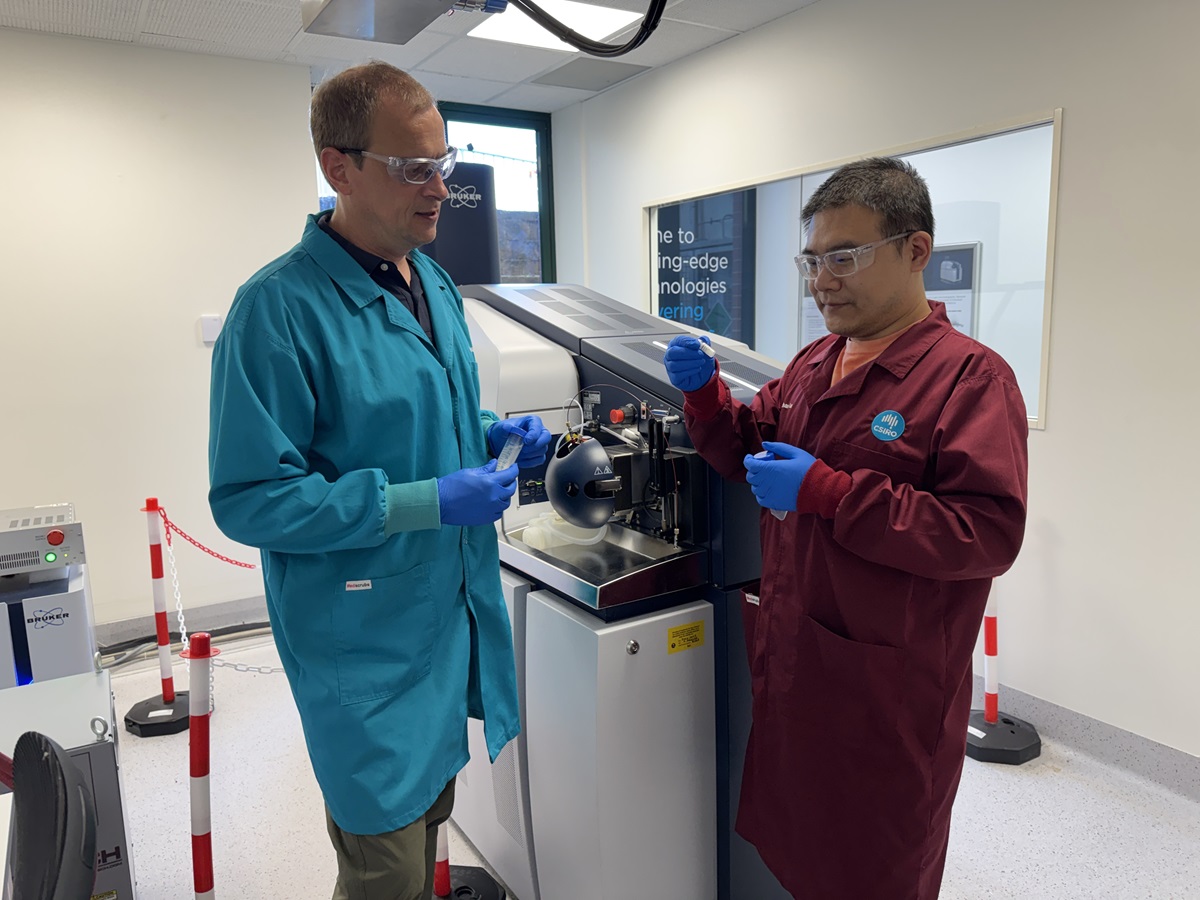

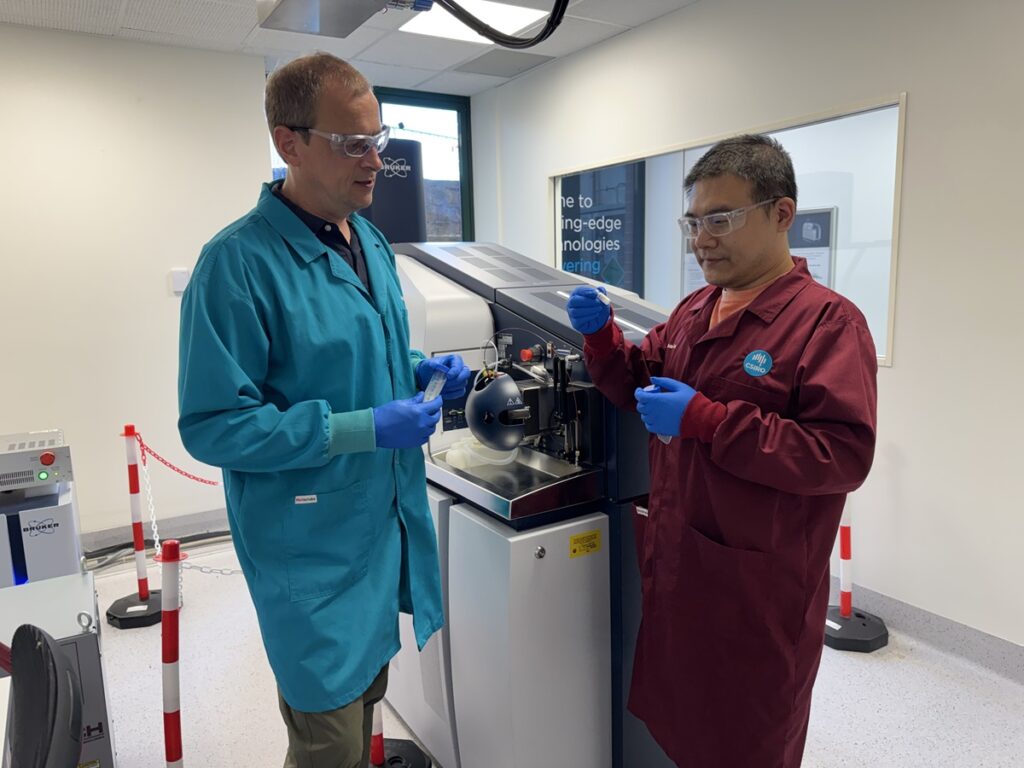

A promising approach to dispose of PFAS involves exposing these chemicals to high temperatures. Various technologies are in use, but this process can create harmful airborne particles, including potent greenhouse gases. An international team of researchers, including Dr. Jens Blotevogel, a Principal Research Scientist at Australia’s national science agency CSIRO, is now focused on identifying these airborne particles to prevent their release into the environment.

Understanding PFAS Destruction

Dr. Blotevogel noted that the carbon-fluorine bonds in PFAS are among the strongest known in chemistry, making these substances resistant to natural degradation. Consequently, specialized treatment methods are essential for effective removal and destruction. The leading techniques include burning PFAS-impacted matter in specialized hazardous waste incinerators or vaporizing the contaminants to preserve the soil structure for reuse, a method known as thermal desorption.

“When we put PFAS-impacted materials in a kiln to destroy them, the aim is to break them down into relatively harmless end products, like carbon dioxide and fluorine,” Dr. Blotevogel explained. He emphasized that PFAS starts to break down at temperatures between 200°C and 700°C, transitioning into gas and forming numerous intermediary compounds. Although many of these intermediaries are short-lived, some can create even more stable bonds requiring temperatures around 1,000°C for complete breakdown.

If these PFAS fragments escape into the atmosphere, they can travel significant distances, contributing to environmental pollution and greenhouse gas emissions. Fortunately, researchers have identified that proper treatment can eliminate these intermediaries entirely. Before emissions leave the incineration facility, they must pass through a scrubber that captures fluorine emissions, ensuring that only steam is released.

Advancing Measurement Techniques

Facilities tasked with PFAS destruction adhere to strict standards, requiring an elimination rate of 99.99 percent or more of these chemicals. While various techniques have been developed to assess PFAS levels in solids and liquids, further research is essential to evaluate gaseous forms effectively. Dr. Blotevogel and his colleagues from institutions such as the Colorado School of Mines, North Carolina State University, and the U.S. Environmental Protection Agency are investigating the gases produced by current and emerging PFAS destruction technologies.

“To determine how much PFAS has been destroyed, it is crucial to employ a range of techniques that measure what’s formed in solid, liquid, and gas phases,” Dr. Blotevogel stated. This task presents significant challenges, requiring a combination of lab experiments, theoretical insights, and multiple lines of evidence to ensure effective PFAS removal.

Researchers aim to develop real-time methods for monitoring the chemical transformations during combustion, complemented by regular emissions testing that focuses on harmful intermediaries. As countries invest billions of dollars in cleaning PFAS-contaminated sites, understanding the fate of these chemicals during destruction is becoming critical.

Dr. Blotevogel concluded, “If we do this right, we can destroy PFAS safely and effectively.” By advancing measurement techniques and understanding the byproducts of PFAS destruction, this collaborative research effort seeks to ensure that solutions for removing these harmful substances do not inadvertently create new environmental issues.