Researchers at North Carolina State University have developed a novel polymer structure dubbed the “Chinese lantern,” capable of transforming into more than a dozen different shapes. This innovative design allows for rapid shape-shifting through compression or twisting, with the added benefit of remote control via a magnetic field.

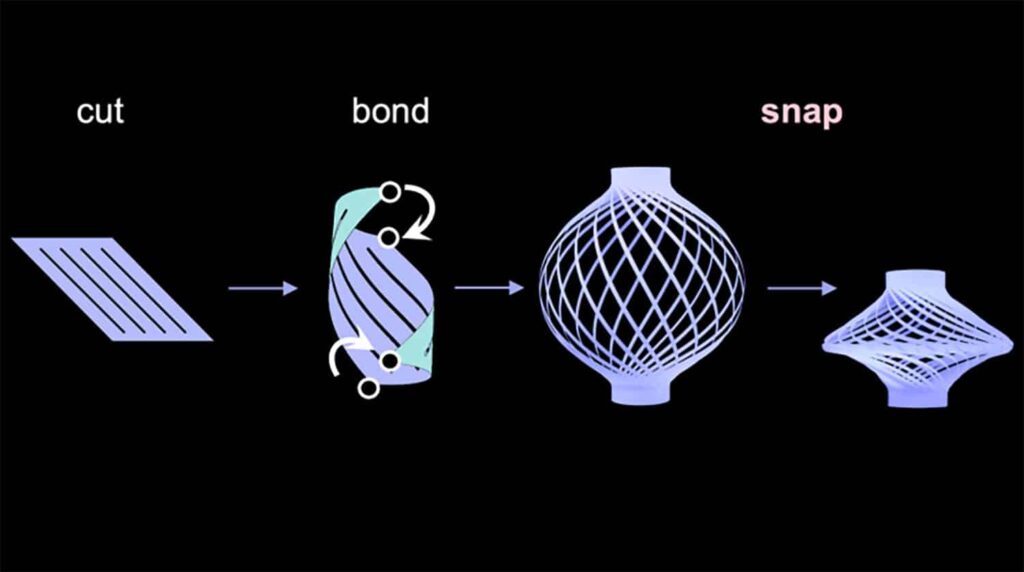

The fundamental design of the lantern begins with a polymer sheet cut into a diamond-like parallelogram. By making parallel cuts across the center, the researchers create a series of ribbons interconnected by solid strips at the top and bottom. When the ends of these strips are joined, the structure morphs into a three-dimensional shape resembling a lantern.

Jie Yin, a professor of mechanical and aerospace engineering and the corresponding author of the study, explains the mechanics behind this bistable design. “This basic shape is, by itself, bistable,” he states. “It is stable in its lantern shape, but if you compress the structure, it will slowly deform until it reaches a critical point, at which point it snaps into a second stable shape resembling a spinning top.”

The spinning-top form holds the energy from the compression, which is released rapidly when the structure is pulled upward, snapping back to its original lantern shape.

In the research, Yaoye Hong, the first author and a former Ph.D. student at NC State now at the University of Pennsylvania, highlights the versatility of the design. “We found that we could create many additional shapes by applying a twist to the structure or folding the solid strips at the top or bottom,” he notes. Each of these variations exhibits multistable properties, with some able to switch between different stable states based on compression, twisting, or a combination of both.

The researchers have also integrated a thin magnetic film into the design, enabling remote manipulation of the shapes through a magnetic field. They demonstrated several practical applications for this technology, including a noninvasive gripper for handling fish, a filter that can open and close to regulate water flow, and a compact shape that quickly expands into a tall form to open a collapsed tube.

A mathematical model developed alongside the research captures the relationship between the angles within the structure and the resulting shape variations. “This model allows us to program the shape we want to create, how stable it is, and how powerful it can be when stored potential energy snaps into kinetic energy,” says Hong.

Jie Yin envisions broader applications for these lantern units, suggesting they can be assembled into two-dimensional and three-dimensional architectures for use in shape-morphing mechanical metamaterials and robotics. “We will be exploring that,” he adds.

The findings are detailed in the paper titled “Reprogrammable snapping morphogenesis in freestanding ribbon-cluster meta-units via stored elastic energy,” published in the journal Nature Materials. The study received funding from the National Science Foundation under grants numbered 2005374, 2369274, and 2445551.