Recent research from the Massachusetts Institute of Technology (MIT) has revealed unexpected atomic patterns in metal alloys that persist during manufacturing. Traditionally, it has been believed that the arrangement of atoms in these materials is random; however, this study challenges that notion, suggesting that specific patterns can enhance the properties of metals, such as mechanical strength, durability, and resistance to radiation.

New Insights into Metal Manufacturing

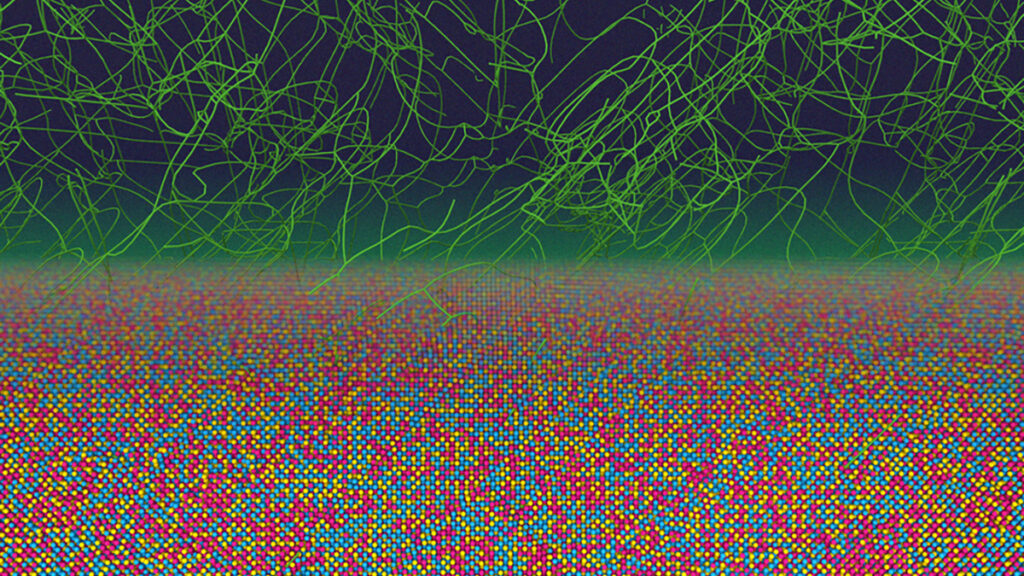

The investigation, detailed in the journal Nature Communications, utilized advanced computer simulations to observe the behavior of millions of atoms in a chromium, cobalt, and nickel alloy (CrCoNi) during common manufacturing processes like rapid cooling and extensive stretching. The findings indicate that atomic arrangements, known as short-range order (SRO), can survive even after intense deformation.

Rodrigo Freitas, a materials scientist at MIT, stated, “This is the first paper showing these non-equilibrium states that are retained in the metal. Right now, this chemical order is not something we’re controlling for or paying attention to when we manufacture metals.” This new understanding could lead to innovative approaches in the production and application of metal alloys.

Researchers found that certain atomic patterns, which would typically be expected to dissipate after rapid deformations, remained intact. Additionally, they identified new atomic configurations they refer to as “far-from-equilibrium states.” These formations are crucial for understanding how metals can be engineered to meet specific performance criteria.

The Role of Defects in Atomic Arrangement

One of the critical factors influencing these atomic patterns is the presence of defects, or dislocations, within the metal’s crystal structure. These defects, which occur during the heating, cooling, or stretching of metals, play a significant role in how atoms rearrange themselves. According to Freitas, “These defects have chemical preferences that guide how they move.” The research suggests that this movement is not entirely random; atoms tend to seek paths of lower energy when rearranging.

The implications of this discovery are vast, particularly in industries reliant on metal alloys, such as aerospace and nuclear engineering. By understanding these hidden patterns, manufacturers could fine-tune the properties of metals in ways that were previously unconsidered. This could lead to significant advancements in material performance for applications ranging from nuclear reactors to spacecraft.

In conclusion, the study highlights an essential aspect of metal manufacturing: it is impossible to completely randomize the arrangement of atoms within a metal, regardless of the processing techniques used. Freitas emphasized, “The fact that you cannot completely mix something together, people didn’t see that coming.” Future research is likely to delve deeper into these findings, potentially revolutionizing how metal alloys are designed and utilized.