A groundbreaking study from the Massachusetts Institute of Technology (MIT) has revealed that metal alloys contain hidden atomic patterns that persist even after intense manufacturing processes. This research challenges the conventional belief that atoms in metal alloys are randomly arranged during production. Instead, it highlights the potential to manipulate the properties of metals, such as mechanical strength and radiation tolerance, by understanding these atomic arrangements.

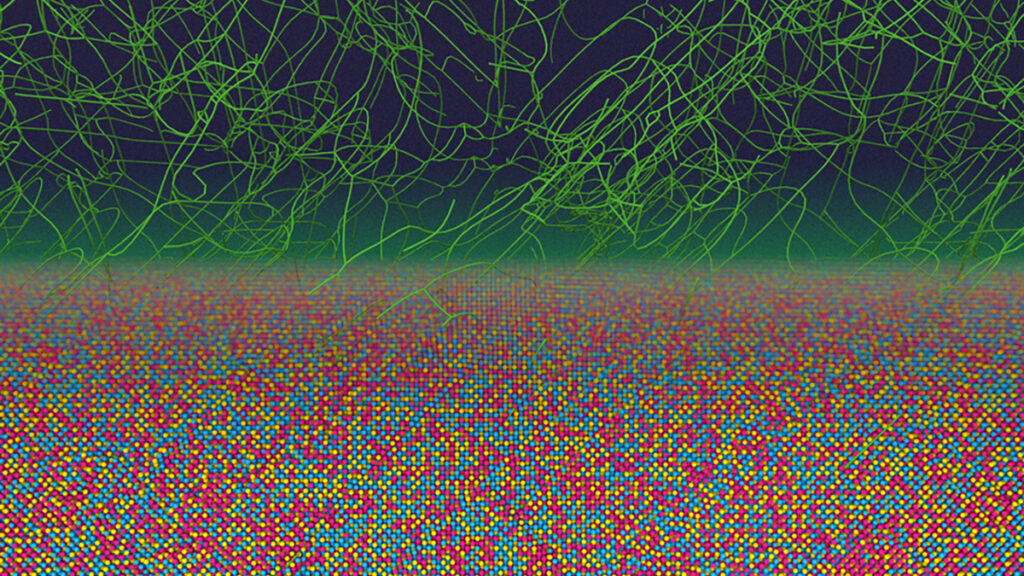

The findings, published in Nature Communications, stem from detailed computer simulations exploring the behavior of millions of atoms in an alloy composed of chromium, cobalt, and nickel (CrCoNi) during common manufacturing practices, such as rapid cooling and extensive stretching. The simulations uncovered both familiar atomic patterns and newly identified ones termed “far-from-equilibrium states.”

Reassessing Metal Alloy Manufacturing

According to Rodrigo Freitas, a materials scientist at MIT, this research is significant as it presents the first evidence of non-equilibrium states retained in metals post-processing. “Right now, this chemical order is not something we’re controlling for or paying attention to when we manufacture metals,” Freitas noted. The study examines the concept of chemical short-range order (SRO), which refers to the specific arrangements that atoms adopt within metal alloys.

The researchers observed that, contrary to prior assumptions, atomic patterns could survive the deformations experienced during processing. The simulations indicate that defects, or dislocations, in the metal’s crystal structure play a crucial role in maintaining these patterns. These defects act like atomic-level scribbles, allowing the metal to endure the stress imposed on it during manufacturing.

Implications for Future Metal Applications

The implications of these findings extend far beyond academic interest. The ability to manipulate atomic patterns could lead to advancements in various fields, including nuclear technology and aerospace engineering. Freitas emphasized the importance of this discovery, stating, “The conclusion is: you can never completely randomize the atoms in a metal. It doesn’t matter how you process it.”

This insight opens up a new frontier in materials science, suggesting that the properties of metal alloys can be fine-tuned in ways previously unconsidered. Future research will likely focus on the specific effects these atomic patterns have on the performance and durability of metals under different conditions.

As the study illustrates, the atomic structure of metals is more complex than previously understood. The persistence of these hidden patterns offers a promising avenue for enhancing metal performance across a range of applications, ultimately leading to stronger and more resilient materials in critical industries.