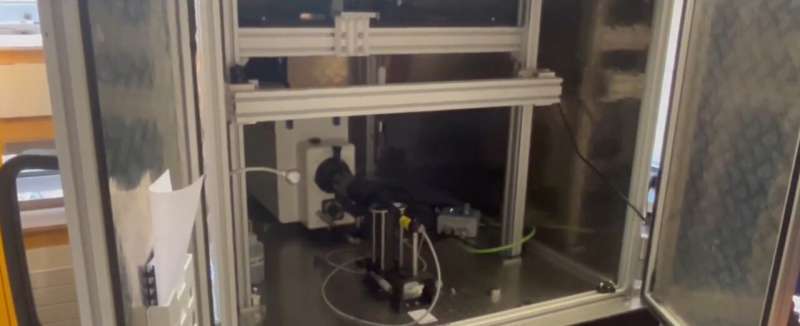

Researchers at Trinity College Dublin have developed a pioneering machine that allows scientists to observe the behavior of microscopic particles when they collide with surfaces at very high speeds. The device, known as the Laser Ablation Particle Acceleration and Observation (LAPAO) machine, is unique in Europe and took over two years to design and construct. This innovative machine enables real-time observation of particles far smaller than a grain of sand, traveling at speeds of up to 1 km per second—approximately three times the speed of a bullet.

The LAPAO machine, built by Trinity’s Science & Technology in Advanced Manufacturing (STAM) research group, utilizes a high-powered laser to propel particles measuring between 10 and 60 microns in size toward a target. A specialized camera captures up to a billion images per second, revealing critical insights about how these particles interact with surfaces. Researchers can now answer fundamental questions about whether particles stick, bounce, or break upon impact, knowledge that is crucial for improving materials and coatings used in various industries, including aerospace and medical technology.

Understanding the behavior of these particles is particularly important for optimizing the “Cold Spray” process, a technique that enables the repair and manufacturing of metal parts without the need to melt materials. Previously, engineers relied on computer models to predict particle behavior, which often lacked accuracy. With the advent of the LAPAO machine, they can now visualize actual material interactions, significantly enhancing the design and manufacturing of advanced materials.

Leo Devlin, a Ph.D. candidate in Trinity’s School of Engineering and a key member of the STAM team, emphasized the importance of this technology, stating, “Thanks to our machine, we can now obtain material parameters for micro-particles undergoing ultra-high strain rate plastic deformation, which modelers have struggled to predict accurately.”

The LAPAO machine has already provided valuable data on the critical velocities of various materials, including aluminum, Ti64, and high entropy alloys. These materials are vital in sectors such as automotive and electrical engineering due to their desirable properties, including high wear and corrosion resistance.

In recent years, cold spray technology has undergone significant advancements, incorporating methods such as laser-assisted and electromagnetism-assisted cold spray to enhance the microstructure and performance of deposited materials. This technology enables the formation of metallic coatings on substrates without reaching the melting temperatures typically required for traditional methods.

Prof. Shuo Yin, a member of the STAM team, highlighted the expanding applications of cold spray technology, noting that it has moved beyond its traditional aerospace applications to encompass the nuclear and broader manufacturing sectors.

In addition to its primary functions, the LAPAO machine can simulate various high-velocity microscale impact events, such as debris impacts on satellites. As the issue of space debris grows, this capability becomes increasingly relevant for protecting valuable equipment in orbit.

Prof. Rocco Lupoi, another member of the STAM team, remarked on the wide-ranging implications of the LAPAO machine. He stated, “Any particle impact can now be studied using any real shape, and we are already utilizing this technology in a project called MadeCold, which is developing a new type of cold spray based on electrostatic acceleration of single particles.”

The LAPAO machine is poised to transform how researchers study particle behavior, offering unprecedented insights that will advance the fields of materials science and engineering. As the team continues to explore the machine’s potential, they anticipate significant contributions to various industries reliant on advanced materials and coatings.