Researchers at Rice University have made significant strides in developing a new bioplastic that could serve as a viable alternative to traditional petroleum-based plastics. The innovative material, known as BCBN (bacterial cellulose-hexagonal boron nitride), leverages the unique properties of bacterial cellulose combined with advanced engineering techniques to enhance its mechanical performance.

The breakthrough centers on a novel approach to cultivating bacterial cellulose. Instead of allowing the bacteria to grow randomly, the researchers manipulate their movement within a bioreactor. By rotating the microbial environment, they achieve a precise alignment of cellulose fibers, which enhances the material’s strength and flexibility. According to M.A.S.R. Saadi, a key researcher in the study, “Instead of having the bacteria move randomly, we instruct them to move in a specific direction, thus precisely aligning their cellulose production.” This method not only improves the mechanical properties but also allows for the incorporation of various nanoscale additives directly into the cellulose matrix.

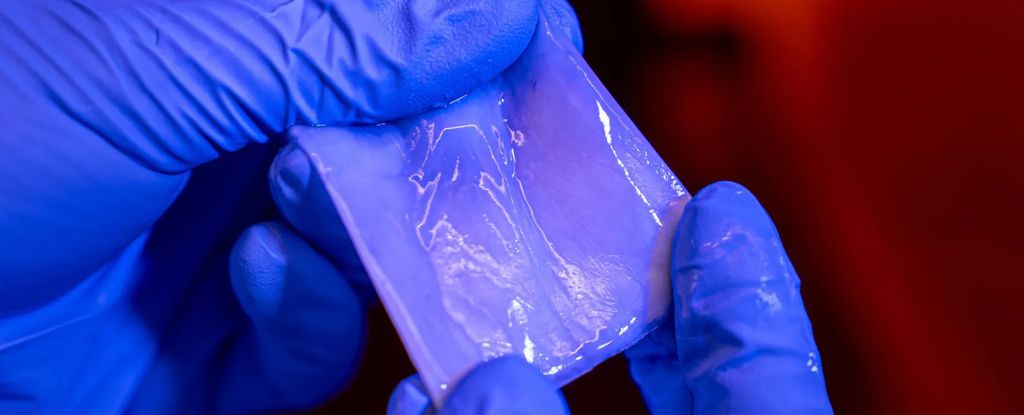

By employing this spinning technique, the research team successfully produced flexible, transparent sheets with a tensile strength of up to 436 megapascals, comparable to that of low-carbon steel. The addition of hexagonal boron nitride nanosheets to the nutrient solution further enhanced the material’s capabilities. This modification resulted in a remarkable increase in tensile strength to 553 megapascals and improved thermal conductivity, allowing the material to dissipate heat three times faster than standard bacterial cellulose.

The lead researcher, Muhammad Maksud Rahman, expressed optimism about the potential applications of this biodegradable material. He envisions that these strong, multifunctional, and eco-friendly bacterial cellulose sheets could replace plastics in various industries, including electronics, energy storage systems, and thermal management. “We envision these materials becoming ubiquitous, replacing plastics in various industries and helping mitigate environmental damage,” Rahman stated.

The research findings have been published in the esteemed journal Nature Communications, highlighting the potential of BCBN as a sustainable solution to the growing plastic pollution crisis. As global awareness of environmental issues continues to rise, advancements in materials science like this could play a crucial role in reshaping industries and promoting a more sustainable future.

In summary, the innovative work at Rice University not only addresses the urgent need for alternatives to conventional plastics but also demonstrates the possibilities of biotechnological advancements in material science. With ongoing research and development, BCBN could soon transform the landscape of everyday products, paving the way for a cleaner and greener planet.