Researchers at the UNSW SMaRT Centre have published a groundbreaking study demonstrating new purification applications for textile and other waste materials. Their latest findings, featured in a report by Elsevier, reveal how waste textiles can be transformed into activated carbon, a crucial component for various purification systems. This innovative approach aims to enhance sustainability in global filtration processes while addressing the growing environmental issues associated with traditional activated carbon production.

The research led by the UNSW Sustainable Materials Research and Technology (SMaRT) Centre showcases a significant advancement in sustainable practices. The team has previously explored the extraction of activated carbon from diverse waste streams, including end-of-life cotton products, automotive shredder residue, and even waste coffee grounds. The study highlights the potential to convert textile waste—often destined for landfills—into valuable materials for water, air, and gas purification, as well as for critical industrial applications.

Professor Veena Sahajwalla, Director of the SMaRT Centre, emphasized the importance of these findings, noting that they present substantial sustainability advantages over conventional methods of producing activated carbon. “We show it is very possible to help ameliorate the growing waste textiles problem while reforming this waste stream into highly valued activated carbon materials,” she stated. The research indicates a remarkable 36% reduction in embodied carbon and over 99% reduction in embodied energy demand compared to traditional coal-derived activated carbon.

Innovative Approaches and Environmental Impact

Activated carbon is a specially treated form of carbon known for its porous structure, making it effective for filtering and purifying liquids and gases. The SMaRT Centre’s latest study involved a lifecycle assessment, reinforcing the momentum towards developing innovative microrecycling technologies. This research aims to tackle “hard to recycle” waste streams efficiently, contributing to a circular economy.

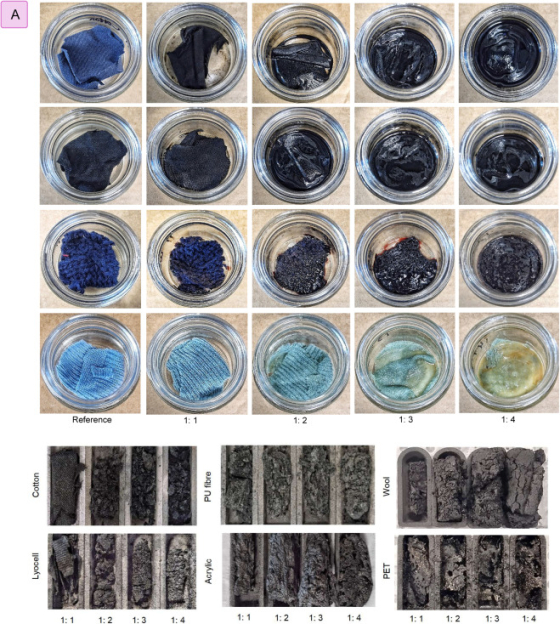

The study’s authors systematically examined the carbonisation and activation behaviors of 14 common textile types. These included cotton, polyester, and wool, among others, to determine their viability for producing activated carbon. The production process involved key steps such as thermal transformation and activation. By optimizing parameters like impregnation ratios and activation temperatures, researchers achieved precise control over the activated carbon properties, tailoring them for specific purification applications.

The findings indicate that 11 out of the 14 textile types are suitable for activated carbon production, while materials like polyurethane and leather showed less favorable results. This knowledge allows for efficient pre-sorting of materials prior to conversion, enhancing the overall recycling process.

Addressing the Global Textile Waste Challenge

The research comes at a critical time, as the global textile industry faces mounting pressure from increasing post-consumer textile waste. Current estimates indicate that approximately 92 million tonnes of textile waste is generated annually, with projections suggesting an increase to 134 million tonnes by 2030. This trend poses significant environmental challenges, including greenhouse gas emissions and microplastic pollution.

The SMaRT Centre’s approach aligns with multiple United Nations Sustainable Development Goals (SDGs). The research not only supports SDG 6 (Clean Water and Sanitation) and SDG 12 (Responsible Consumption and Production) but also contributes to efforts in reducing industrial emissions and enhancing sustainable practices within the textile industry.

In Australia, the situation is particularly urgent. The country ranks among the highest per capita consumers of textiles, with average annual consumption around 27 kilograms per person. Unfortunately, a substantial portion of this waste—around 93%—ends up in landfills. The SMaRT Centre’s research aims to mitigate these pressing issues by transforming textile waste into high-value activated carbon, fostering a more sustainable future.

The UNSW SMaRT Centre’s research represents a promising step towards a circular economy, where waste materials can be effectively recovered and repurposed. As pilot and industrial-scale technologies are developed, the team hopes to expand its innovative MICROfactorieTM systems, which currently include modules for plastics and green ceramics.

This research was supported by the Australian Research Council’s Industrial Transformation Research Hub funding scheme. The findings signal a crucial advancement in both environmental sustainability and the potential for significant economic impact through the valorization of waste materials.