Demonstrating the latest in agricultural technology, McIntosh & Son showcased the New Holland CR11 header during a community wheat harvest on a 100-hectare crop near Wyalkatchem, Western Australia. The event, held last Friday, highlighted the innovative features of the new machine, which is designed to enhance productivity for broadacre graingrowers.

Local grain producer Campbell Jones, who operates between Koorda and Wyalkatchem, volunteers annually to assist with the community crop. “I just help out when I can; Will Nightingale does a fair bit, and Nutrien Ag Solutions handles the agronomy work,” Jones explained. This year’s wheat variety, Vixen, yielded around two tonnes per hectare, a slight decrease from last year’s average of 2.6t/ha. Jones attributed the drop to a challenging growing season, receiving only 190 millilitres of rainfall.

The funds generated from the community crop are directed toward local sports clubs, with recent contributions including new greens for the bowling club and renovation work at the golf club.

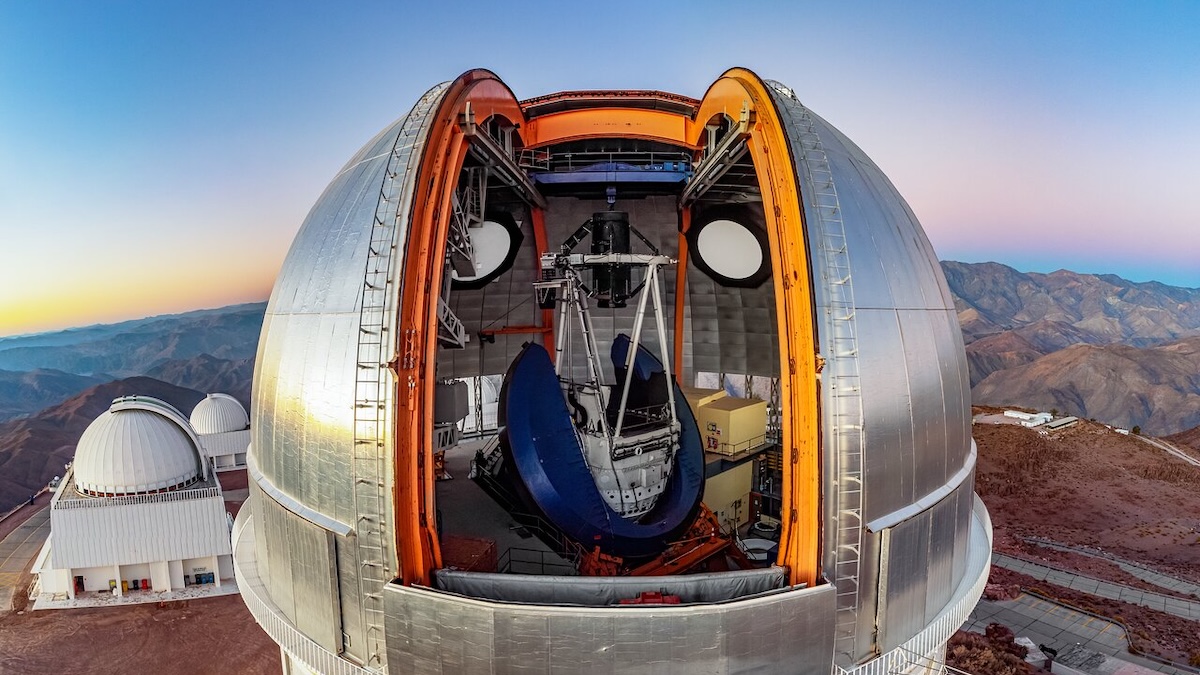

Revolutionary Features of the CR11

Sales representative Kyle Finlay from McIntosh & Son’s Cunderdin branch operated the CR11 during the demonstration. This model represents a significant redesign compared to its predecessors, featuring a C16 Cursor engine that delivers 775 horsepower and a grain tank capacity of 20,000 litres, capable of unloading at a rate of 210 litres per second.

The machine’s rotors are wider in diameter and longer than previous models, enhancing its efficiency in the field. With dual rotary technology and an innovative processor, the CR11 aims to meet the demands of large-scale grain operations focusing on efficiency and shorter harvest windows. “It’s an absolute beast,” Finlay remarked. “It’s performing well, and obviously, it’s a good new product to have out on the market. With FieldOps engaged, it can achieve 75 tonnes per hour, compared to around 45t/hr for the CR9 and CR10 models.”

Finlay also noted the machine’s ability to efficiently spread residue across a full 60 feet behind the front. This feature offers significant agronomic and logistical advantages, as it eliminates the need for a second pass over the harvested area. “We’ve got tighter crops per paddock in Cunderdin; there are too many rocks and trees to just run a 60-footer through,” he said.

Harvest Outlook and Community Impact

According to Anthony Ryan, general manager of northern branches at McIntosh & Son, the first season of CR11 demonstrations is crucial. “Our teams are in the field at every startup, assisting with configurations, conducting harvest loss tests, and ensuring our customers get the best out of the machine,” Ryan stated. He emphasized that the combination of capacity, sample quality, residue management, and in-cab automation is proving to be transformative for many operators.

The overall harvest in Cunderdin is reportedly performing well, despite initial concerns in June about the potential yield. “From what it looked like back then, it didn’t seem like there would be much of a harvest at all,” Finlay noted. “It just goes to show things can turn around. Now we’re looking at a record harvest.” He pointed out that similar conditions last year led to unexpectedly good crop yields, highlighting the unpredictable nature of farming.

The community’s investment in the harvest not only supports local sports facilities but also fosters a sense of cooperation and resilience among graingrowers. As they adapt to the challenges of climate and market conditions, innovations like the CR11 header are set to play a pivotal role in shaping the future of grain production in Western Australia.