Researchers from Rice University have made significant strides in the search for sustainable alternatives to petroleum-based plastics. Their innovative biomaterial, known as BCBN (bacterial cellulose-hexagonal boron nitride), harnesses the natural abilities of bacteria to create a highly functional and eco-friendly product. This development holds promise for a wide array of applications across various industries.

The key to this breakthrough lies in the unique method employed by the research team. By rotating the bacteria within a bioreactor, the team aligns the cellulose fibers as they grow. This alignment enhances the mechanical properties of the resulting material, allowing it to match or even surpass the strength of some metals and conventional plastics.

M.A.S.R. Saadi, a member of the research team, explained the process: “Instead of having the bacteria move randomly, we instruct them to move in a specific direction, thus precisely aligning their cellulose production.” This technique enables the seamless integration of nanoscale additives into the bacterial cellulose, facilitating the customization of material properties for specific uses.

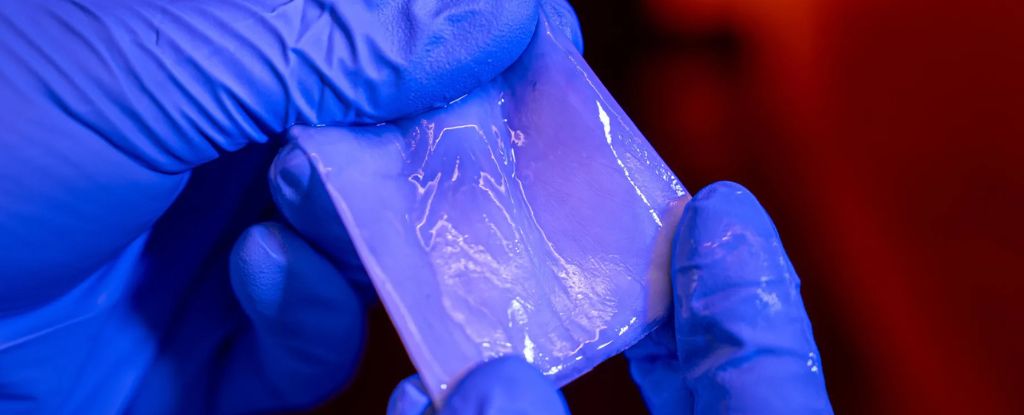

The researchers successfully produced flexible, transparent sheets with a tensile strength reaching up to 436 megapascals, comparable to low-carbon steel. When hexagonal boron nitride nanosheets were incorporated into the nutrient solution for the bacteria, the performance of the material improved significantly. The new composite not only dissipated heat three times faster than standard bacterial cellulose but also increased the tensile strength to 553 megapascals.

Muhammad Maksud Rahman, the lead researcher, expressed optimism about the potential of this biodegradable material. “We envision these strong, multifunctional and eco-friendly bacterial cellulose sheets becoming ubiquitous, replacing plastics in various industries and helping mitigate environmental damage,” he stated.

The research findings were published in the esteemed journal Nature Communications, highlighting the importance of this advancement in the ongoing effort to reduce reliance on harmful plastics. The implications of this work extend beyond mere innovation; it represents a crucial step towards addressing the environmental challenges posed by traditional plastics.

As the world grapples with the urgent need for sustainable materials, the development of BCBN could pave the way for new solutions in fields such as electronics, energy storage, and thermal management. The ability to produce a versatile and environmentally friendly material could transform industries and contribute to a more sustainable future.

In conclusion, the work by Rice University researchers exemplifies how advancements in materials science can lead to significant improvements in sustainability and functionality. The development of BCBN not only showcases the potential of bioplastics but also underscores the critical need for continued innovation in addressing global environmental challenges.